i have had a number of guys ask me about the mutant motor i am doing. i had it posted on here for a while then took it off. seems like things have died down so i'll attempt it again. i'm just going to start it off where i left off on prior thread i had post.

i revised the crank a lil and reduced weight even more with weight savings on rod about a lb lighter than the stock xr 100 crank

![Image]()

![Image]()

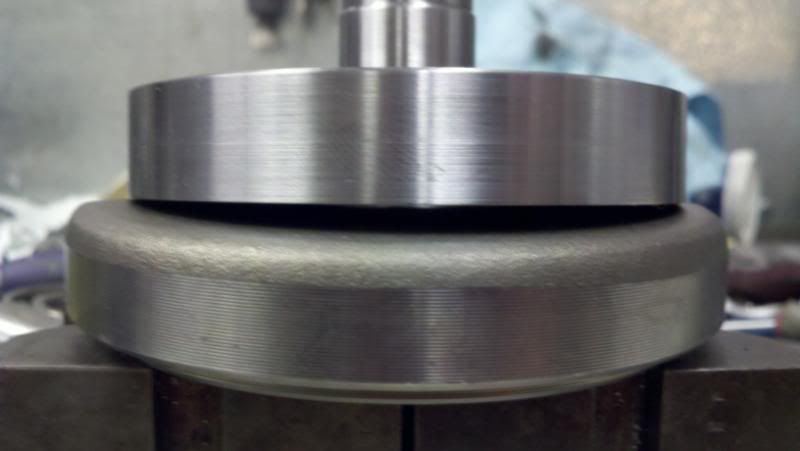

stock on bottom cut halve on top

![Image]()

![Image]()

piston with 55mm stroke 100mm rod.

![Image]()

![Image]()

cut down to give myself .020th clearance

![Image]()

![Image]()

![Image]()

i revised the crank a lil and reduced weight even more with weight savings on rod about a lb lighter than the stock xr 100 crank

piston with 55mm stroke 100mm rod.

cut down to give myself .020th clearance